Solar sludge dryers use sunlight energy for drying. Solar drying of sludge differs from other sludge drying technologies primarily by the process temperature. In disc, drum or fluidized dryers, water evaporation occurs at temperatures above 100 °C. In solar dryers, the process is carried out at lower temperatures using the greenhouse effect. Low-wavelength solar radiation passing through the atmosphere reaches the dryer. Part of the radiation is reflected from the coating of the dryer and is dispersed, most of it reaches the dried sludge causing its heating. The own radiation of the sludge is emitted via longer wavelengths (infrared radiation). Part of the infrared radiation is reflected from the cover of the dryer, which causes the temperature inside the hall to rise. The greenhouse effect releases significant amounts of energy, which is used to intensify the water evaporation process.

The speed of sludge drying process depends mainly on the intensity of solar radiation (the amount of heat supplied to the dried sludge bed, drying air temperature and its relative humidity, drying air speed, bed size, bed thickness).

Solar sludge dryers are solutions characterized by the lowest operating costs. The process uses free solar energy and a small amount of electricity needed to operate the turner and ventilation system.

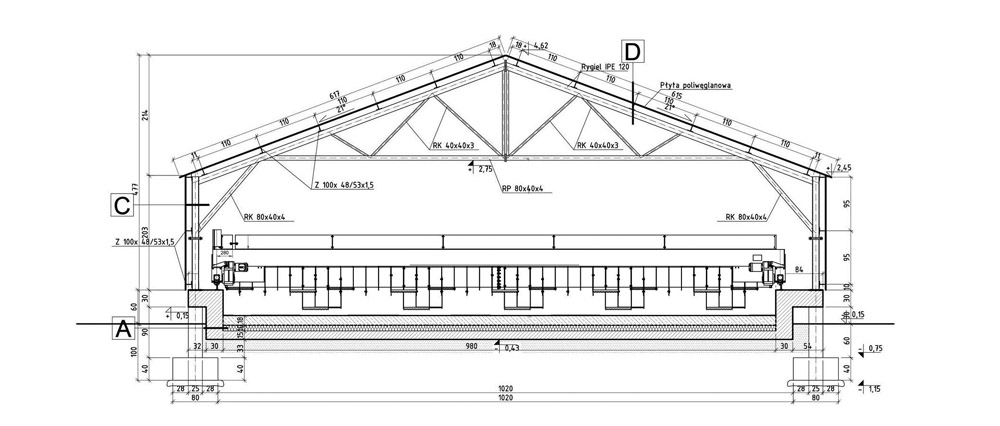

The technology developed at UCB Warsaw University of Technology assumes as a basis the use of sunlight energy in properly constructed halls allowing the greenhouse effect to take place. The halls are equipped with the following installations:

One of the key equipment of the technology is the control system, including the ventilation control system. The ventilation system control algorithm is responsible for switching on the exhaust fans to exchange the air inside the dryer. The control algorithm allows optimal air movement in a solar drying hall regardless of local atmospheric conditions. The key parameter is the potential for moisture collection of the drying air. On the basis of measurements of temperature and humidity of the air outside and inside the dryer, the drying potential of external and internal air is determined. The internal air potential (usually heated but with higher humidity) is compared with the outside air potential (usually cooler but more dry). If the internal air potential is higher then the air should not be exchanged inside the dryer. Otherwise, the exhaust fans responsible for the air exchange in the dryer should be temporarily turned on. Control system is based on programmable controllers that manage the whole drying process.